From empty hall to modern production space without downtime.

April 2022: Furniture maker and lacquer Verdonck moves to a new location, tripling its surface area. Dirty empty halls are converted into a modern production area with heavy machinery. But without electricity, of course, these will not run. In addition, the right lighting is essential to be able to work accurately. GIEC provided a safe power supply to the machines. And the lighting? We worked out something special for that.

Furniture maker Verdonck from Lokeren was founded in 1930. Today, the 3rd generation is at the helm of a 20-strong team of experts. Their craftsmanship translates into high-quality kitchens, bathrooms, dressing rooms and all customization for high-end interior, shop and museum furnishings. In the paint shop, they guarantee a high-quality finish and the right color for piece and series work via wet painting, staining, varnishing or cerusé.

And that quality is appreciated: the company is experiencing strong growth, as a result of which the rental location is no longer sufficient. The lack of space makes it difficult to work efficiently: employees, materials and machines need more space.

Larger location due to strong growth

When a building comes up for sale in the same industrial estate, the furniture workshop finds a new home. Thanks to the investment, the company has tripled its surface area! The polluted buildings, formerly used by a producer and collector of frying oil, are being cleaned and given a new purpose as a modern production space.

The empty halls are like a blank slate. Lighting and machines still have to find their place and of course need power. Manager Stijn Verdonck approached GIEC for this.

“In the past, GIEC N.V. engaged us for some of the agencies. In addition, we have also been ‘neighbouring companies’ in industrial estate E17 of Lokeren for many years. It was therefore logical for me to approach GIEC for this project,” says Stijn Verdonck, manager at Meubelmakerij en Lakkerij Verdonck.

From empty hall to modern production space

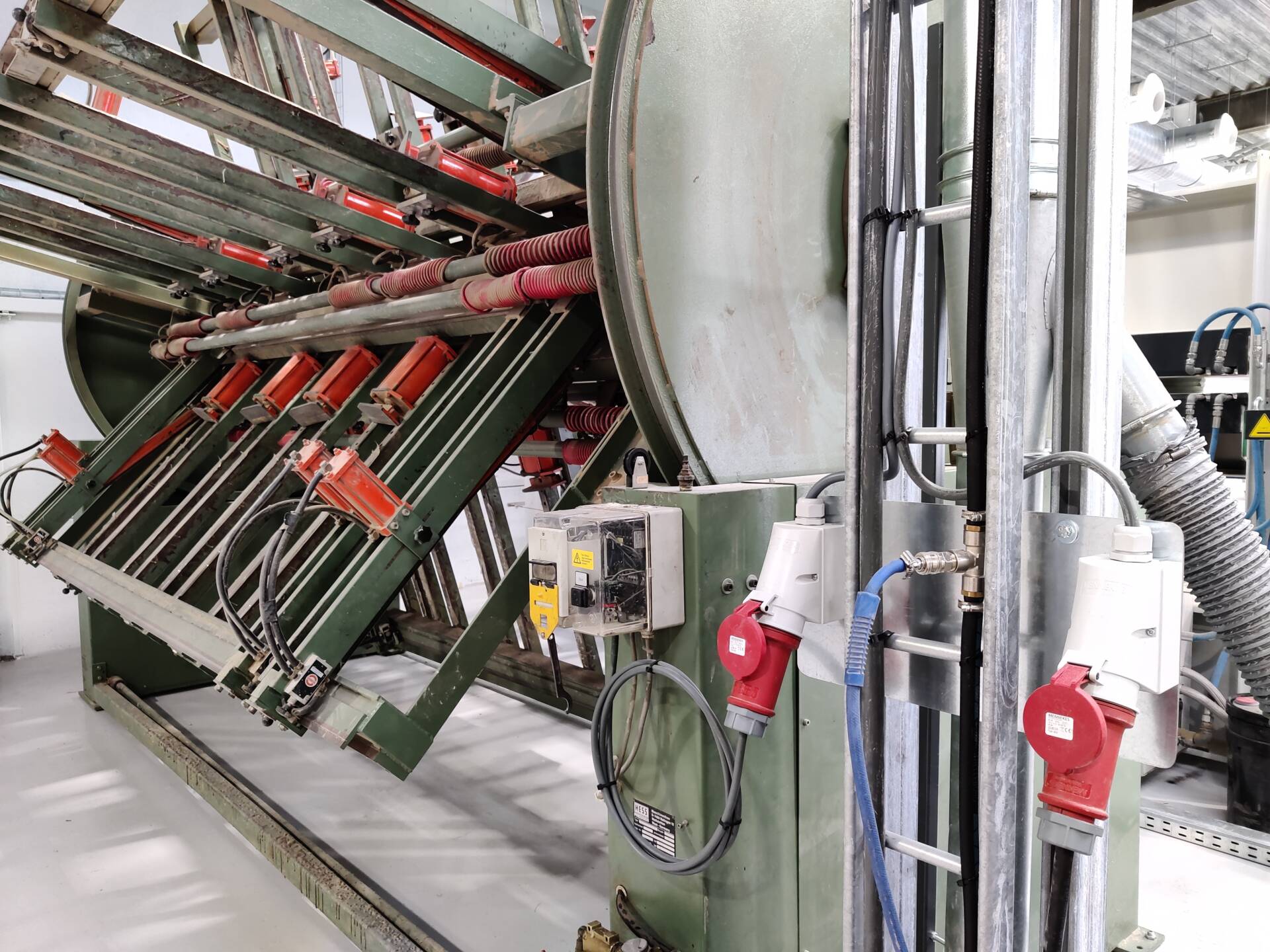

“GIEC was responsible for the design of the electrical diagrams and all cable calculations to arrive at a compliant electricity installation. With a team of 6 employees, we then took care of the delivery and installation of cable-ways such as cable ladders, wire nets and PVC pipes and cables for the power supply of the machines and data communication. We also installed the sockets and lighting,” says Thomas Van Gansen, project leader at GIEC.

“Lighting is very important in furniture making. Employees who are directly under a lamp and therefore in their own shadow cannot work accurately. While some machines just need little light because otherwise their sensors will not work correctly. The installation of the lighting therefore required extra attention. At the request of the customer, these were given separate controls. Is there no production at a certain location? Then the lamps can be switched off per row.”

Patrick Goevaerts, site manager at GIEC adds: “The spacious buildings ensure that the power supply can run directly to the machines. Cables on the ground are a thing of the past, making it easier and safer for employees to manipulate and work. The preparation of the cable-ways and ladders is all done in our own workshop. This allows us to work completely tailor-made. For example, it was no problem to provide a ramp or T-piece for the cable cars.

“In addition to the cabling, we also took care of a large part of the mechanical preparation,” Thomas continues. “This allowed the HVAC and compressed air installer to continue working on the supports we placed.”

Flexible soundboard

“The biggest challenge with this project? That was undoubtedly keeping the downtime as short as possible”, says Patrick. “To power the most important machines as quickly as possible, we installed temporary site mushrooms. We also made sure that we could start work as soon as possible after clearing the halls. The result of our efforts? The production of the furniture workshop was only stopped for 1 week and the paint shop never even. Mission more than successful!”

“In addition, it was difficult to estimate the size of the project in advance,” says Stijn. “During the works I constantly saw opportunities to optimize things. I could always go to GIEC to test my ideas in an open manner. In addition, they controlled closely. Extra manpower on site? Want to order additional material quickly? The team was extremely flexible in order to carry out the requested works as quickly as possible.”

“I like being able to function as a sounding board. And certainly during the project of Meubelmakerij Verdonck: the family atmosphere and the trust of the customer ensured that I enjoyed going to the yard every day,” concludes Patrick.

Do you have questions? Would you like a visit or would you like to discuss a project?

Overview

Location: Lokeren

Client: www.meubelmakerijverdonck.be | www.lakkerijverdonck.be

Implementation:

- Design electrical diagrams and cable calculations.

- Supply and installation of cable-ways (cable ladders, wire nets, PVC pipes) and cables (power supply to machines and data communication).

- Installation of lighting and electrical outlets.

Expertise: Electrical engineering – electrical engineering – panel building